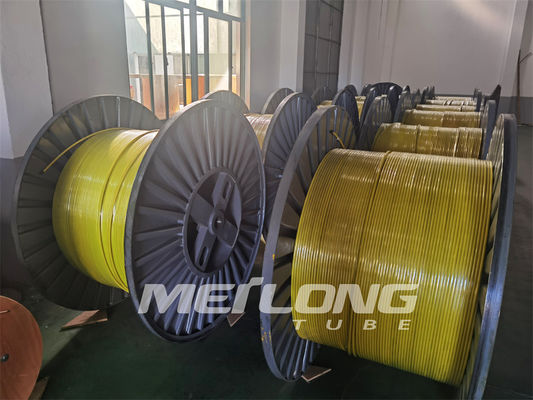

Red Encapsulated Control Line with Close Dimensional Tolerance Highly Clean and Bright Tubing Surface

Product Description:

MEILONG offers the encapsulation of control lines to provide increased durability, as well as chemical and corrosion resistance to meet each project’s specialized requirements, we offer different encapsulation types, such as: HDPE (High Density Polyethylene), Santoprene, PVC (Polyvinyl Chloride), Haylar and PVDF (Polyvinylidene Fluoride).

Encapsulation is a plastic that is extruded over metal tube. It prevents damage to the metal tubes during the manufacturing process, and also provides additional abrasion resistance. Moreover, when cable protectors are installed, encapsulation is required to enhance the holding force over each production tubing connection.

Encapsulations are available in a wide range of configurations, with options of single pass and dual pass encapsulation for added protection. Flatpacks are widely used when several different lines are terminated at the same depth in the well. Common application includes intelligent well systems, deep-set chemical injection lines with downhole gauge cable and safety valve lines with shallow set chemical injection lines. For certain applications, bumper bars are also encapsulated into the flatpack to provide extra crush resistance.

Control lines are created according to relevant materials’ ASTM standard. Tubes can be flush, filled, filtered and supplied to meet client requirements and NAS/SAE standards. Moreover, Encapsulated Control Lines can meet Potable Water Application requirements.

Features:

When encountering downhole line, maximum protection should be put forth. This includes the installation of mechanisms that increase its crush resistance. Additionally, there is a need to protect the control line from potential abrasion and pinching that may be inflicted upon it. It is essential to take precautionary steps to reduce stress corrosion failures that may occur in the long-term. Lastly, when clamping the line, its profile should be improved. Single or multiple casing techniques can be used to make the running of it easier, all the while ensuring added protection.

Technical Parameters:

| Alloy |

UNS |

O.D. |

W.T. |

Working Pressure |

Burst Pressure |

Collapse Pressure |

Test Pressure |

| inch |

inch |

inch |

psi |

psi |

psi |

psi |

| Stainless 316L |

S31603 |

1/8 |

0.125 |

0.028 |

9,931 |

40,922 |

9,525 |

11,600 |

| Stainless 316L |

S31603 |

1/8 |

0.125 |

0.035 |

12,640 |

52,042 |

11,056 |

15,225 |

| Stainless 316L |

S31603 |

1/4 |

0.250 |

0.035 |

5,939 |

24,474 |

6,621 |

7,250 |

| Stainless 316L |

S31603 |

1/4 |

0.250 |

0.049 |

8,572 |

35,322 |

8,632 |

10,150 |

| Stainless 316L |

S31603 |

1/4 |

0.250 |

0.065 |

11,694 |

48,166 |

10,562 |

13,775 |

| Stainless 316L |

S31603 |

3/8 |

0.375 |

0.035 |

3,818 |

15,731 |

4,659 |

4,350 |

| Stainless 316L |

S31603 |

3/8 |

0.375 |

0.049 |

5,483 |

22,575 |

6,222 |

6,525 |

| Stainless 316L |

S31603 |

3/8 |

0.375 |

0.065 |

7,517 |

30,951 |

7,865 |

8,700 |

| Stainless 316L |

S31603 |

3/8 |

0.375 |

0.083 |

9,808 |

40,372 |

9,551 |

11,600 |

| Stainless 316L |

S31603 |

1/2 |

0.500 |

0.049 |

4,003 |

16,480 |

4,835 |

5,075 |

| Stainless 316L |

S31603 |

1/2 |

0.500 |

0.065 |

5,461 |

22,512 |

6,206 |

6,525 |

| Stainless 316L |

S31603 |

1/2 |

0.500 |

0.083 |

7,133 |

29,364 |

7,648 |

8,700 |

| Stainless 316L |

S31603 |

5/8 |

0.625 |

0.049 |

3,144 |

12,955 |

3,957 |

3,625 |

| Stainless 316L |

S31603 |

5/8 |

0.625 |

0.065 |

4,285 |

17,630 |

5,105 |

5,075 |

| Stainless 316L |

S31603 |

5/8 |

0.625 |

0.083 |

5,472 |

22,513 |

6,519 |

6,525 |

| Stainless 316L |

S31603 |

3/4 |

0.750 |

0.049 |

2,619 |

10,791 |

3,296 |

2,900 |

| Stainless 316L |

S31603 |

3/4 |

0.750 |

0.065 |

3,570 |

14,686 |

4,283 |

4,350 |

| Stainless 316L |

S31603 |

3/4 |

0.750 |

0.083 |

4,558 |

18,753 |

5,431 |

5,800 |

Applications:

When operating an oil & gas facility, down hole tubes, subsea umbilicals, process constructions and general control systems are essential elements for a successful operation. Specifically, down hole tubes are used to maintain the wellhead pressure, subsea umbilicals help connect a wide variety of parts and control systems underwater, process constructions are mainly used to accomplish the design requirements from clients and the general control systems help monitor and control any process in the facility. In addition, steam supply lines and gas transport lines are used for the supply of steam or gas in the optimal condition. Lastly, instrumentation systems are used to monitor the data of the process to ensure safety and reliability of the whole system.

Customization:

Encapsulated Control Line

Meilong Tube provides top quality FEP encapsulated control line, TPV encapsulated injection line, and PVDF encapsulated control line with model number 3/8''OD x 0.049''WT. Our products are certified with ISO9001 and feature a minimum order quantity of 2 coils, packed in wooden cases. Delivery is guaranteed within 7 days of payment via T/T or L/C, and our supply capacity is 150 metric tons per month.

Our encapsulated control lines are designed for down hole application in oil and gas industry and are available in both round and rectangular shapes. Close dimensional tolerance is guaranteed for tubing size as well as a working pressure of above 10000 Psi. We provide encapsulation material like TPV, PVC, PVDF, PP, and FEP.

Support and Services:

Encapsulated Control Line Technical Support and Services

We provide technical support and services to ensure the quality and reliability of Encapsulated Control Line. Our services include:

- Troubleshooting and repairs

- Software and hardware updates

- Product compatibility testing

- Technical documentation

- Product customization

- Training and technical support

If you have any questions or need assistance, please contact our customer service team at [INSERT CONTACT INFORMATION].

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!