ASTM A789 Seamless Super Duplex 2507 Hydraulic Control Line Tubing for Gas Wells

Meilong Tube manufactures high quality seamless and redrawn, seam-welded and redrawn coiled tubing which are made from corrosion-resistant austenitic, duplex, super duplex stainless steel and nickel alloy grades. 100% of products are used as hydraulic power control lines, chemical injection lines, alloy tubing in umbilicals and instrumentation tubing for the exploitation engineering in the upstream oil and gas industry.

Coiled tubing is available in sizes arrange from outer diameter 0.125 inch (3.175 millimeters) to 1 inch (25.4 millimeters). Wall thickness is up to 0.083 inch (2.108 millimeters). Lengths up to 65600 feet (20,000 meters) are available for cost-effective umbilical manufacturing. More sizes within the scope can be customized to be produced and delivered for meeting your special requirements.

Super Duplex 2507 hydraulic control line properties

Seamless & floating internal plug redrawn tubing. Supplied in the annealed condition

Continuous length without orbital joint welds

| Alloy |

UNS |

O.D. |

W.T. |

Working Pressure |

Burst Pressure |

Collapse Pressure |

Test Pressure |

| inch |

inch |

inch |

psi |

psi |

psi |

psi |

| Super Duplex 2507 |

S32750 |

1/8 |

0.125 |

0.028 |

19,177 |

47,169 |

19,177 |

21,025 |

| Super Duplex 2507 |

S32750 |

1/8 |

0.125 |

0.035 |

23,971 |

58,961 |

23,971 |

26,100 |

| Super Duplex 2507 |

S32750 |

1/4 |

0.250 |

0.035 |

11,986 |

29,481 |

11,986 |

13,050 |

| Super Duplex 2507 |

S32750 |

1/4 |

0.250 |

0.049 |

16,816 |

35,949 |

15,817 |

18,850 |

| Super Duplex 2507 |

S32750 |

1/4 |

0.250 |

0.065 |

22,300 |

45,448 |

19,522 |

24,650 |

| Super Duplex 2507 |

S32750 |

3/8 |

0.375 |

0.035 |

8,009 |

25,138 |

8,372 |

8,700 |

| Super Duplex 2507 |

S32750 |

3/8 |

0.375 |

0.049 |

11,205 |

28,536 |

11,296 |

12,325 |

| Super Duplex 2507 |

S32750 |

3/8 |

0.375 |

0.065 |

14,873 |

33,141 |

14,346 |

16,675 |

| Super Duplex 2507 |

S32750 |

3/8 |

0.375 |

0.083 |

18,977 |

39,426 |

17,379 |

21,025 |

| Super Duplex 2507 |

S32750 |

1/2 |

0.500 |

0.049 |

8,408 |

25,532 |

8,753 |

9,425 |

| Super Duplex 2507 |

S32750 |

1/2 |

0.500 |

0.065 |

11,150 |

28,470 |

11,259 |

12,325 |

| Super Duplex 2507 |

S32750 |

1/2 |

0.500 |

0.083 |

14,237 |

32,275 |

13,838 |

15,950 |

| Super Duplex 2507 |

S32750 |

5/8 |

0.625 |

0.049 |

6,719 |

23,918 |

7,137 |

7,250 |

| Super Duplex 2507 |

S32750 |

5/8 |

0.625 |

0.065 |

8,898 |

26,056 |

9,243 |

10,150 |

| Super Duplex 2507 |

S32750 |

5/8 |

0.625 |

0.083 |

11,386 |

35,306 |

11,459 |

12,325 |

| Super Duplex 2507 |

S32750 |

3/4 |

0.750 |

0.049 |

5,593 |

22,921 |

6,029 |

5,800 |

| Super Duplex 2507 |

S32750 |

3/4 |

0.750 |

0.065 |

7,427 |

24,587 |

7,827 |

7,975 |

| Super Duplex 2507 |

S32750 |

3/4 |

0.750 |

0.083 |

9,480 |

26,647 |

9,770 |

10,150 |

- Theoretical burst pressure based on minimum wall thickness, and minimum tensile strength

- Theoretical collapse pressure based on minimum wall thickness, and minimum yield strength

- Pressure rating at 100°F (38°C), neutral and static conditions

As more oil and gas extractions move into deeper and harsher waters where extreme offshore environments demand extreme safety, our work is to help you use the “right” corrosion resistant material for coiled umbilical tubing to improve the safety and reliability of your work. This is the power for driving our innovations and continuous development.

Suitable for Application Environment

Good resitance to chloride pitting, crevice corrosion, H2S and CO2, and chloride stress corrosion cracking (SCC).

Dimensional Tolerance for Hydraulic control line

| ASTM A789 / ASME SA789, UNS S32750 |

| Size OD |

Tolerance OD |

Tolerance WT |

|

1/8’’≤OD<3/16’’ (3.18≤OD<4.76 mm)

3/16≤OD<1/2’’ (4.76≤OD<12.7 mm)

1/2’’≤OD≤1’’ (12.7≤OD≤25.4 mm)

|

+0.003’’ (+0.08 mm) / -0

+0.004’’ (+0.10 mm) / -0

+0.005’’ (+0.13 mm) / -0

|

±10%

±10%

±10%

|

Meilong Tube Standard

| Size OD |

Tolerance OD |

Tolerance WT |

|

1/8’’ ≤OD<3/16’’ (3.18≤OD<4.76 mm)

3/16≤OD<1/2’’ (4.76≤OD<12.7 mm)

1/2’’≤OD≤1’’ (12.7≤OD≤25.4 mm)

|

+0.003’’ (+0.08 mm) / -0

+0.004’’ (+0.10 mm) / -0

+0.004’’ (+0.10 mm) / -0

|

±10%

±10%

±8%

|

Tests for Quality

|

Eddy current

Surface roughness

Hydrostatic

Dimensional analysis

Grain size

Rockwell hardness

|

Yield strength

Tensile strength

Elongation

Hardness

Positive material identification (PMI)

Corrosion resistance tests

|

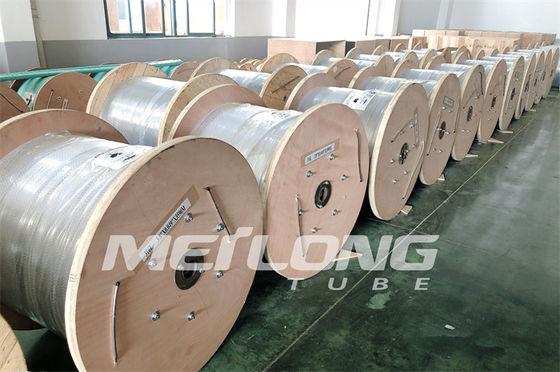

Packing

Hydraulic control line is level wound coiled on the metal / wooden drums or spools.

All drums are packed in wooden crates for easy logistic operation.

Application

Capillary coiled alloy tubing for chemical injection

Bare and encapsulated hydraulic control line coiled alloy tubing for subsea safety valves

Velocity strings, work strings, and steel tube umbilicals

Geothermal coiled alloy tubing

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!