Ferrule Fittings Hydraulic Control Line in Stainless Steel for Down Hole Application In Oil And Gas Industry

Product Description:

Meilong Tube offers high quality tubing products for the oil & gas sector which have been applied in some of the most challenging subsea and downhole conditions. We are proud of our long and proven track record of meeting the stringent requirements of the oil and gas sector.

At Meilong Tube, we provide coiled tubing in a wide range of corrosion resistant stainless steels, nickel alloys. We have significant know-how and expertise in product supply and innovation in this sector, from the technological advances required for subsea developments in the 1999 to deepwater challenges of present days.

We specialize in producing and supplying corrosion resistant tubing products from duplex, nickel alloy and stainless steel grades to suit customer’s specific requirements for applications in upstream oil and gas and geothermal projects.

Features:

Our tubing is characterized by its integrity and quality, making it an ideal choice for subsea conditions in the oil and gas industry.

In this highly demanding environment, where safety and performance are critical, our tubing is a reliable choice, providing easy installation, superior corrosion resistance, and excellent pressure bearing capabilities.

Additionally, our tubing can be tailor-made to the individual needs of any project, providing operators with efficient, cost-effective solutions.

Technical Parameters:

Control line properties is the topic of our discussion. It includes the seamless and floating internal plug redrawn tubing which is supplied in an annealed condition. Continuous length without orbital joint welds.

The alloy, UNS, outside diameter, wall thickness as well as the working pressure, burst pressure, collapse pressure, and test pressure are provided in the table below.Theoretical burst pressure based on the minimum wall thickness and minimum tensile strength.Theoretical collapse pressure based on the minimum wall thickness and minimum yield strength. The pressure rating is at 100°F (38°C), neutral and static conditions.

| Alloy | UNS | O.D. | W.T. | Working Pressure | Burst Pressure | Collapse Pressure | Test Pressure |

|---|

| Stainless 316L | S31603 | 1/8 | 0.125 | 0.028 | 9,931 | 40,922 | 9,525 |

| Stainless 316L | S31603 | 1/8 | 0.125 | 0.035 | 12,640 | 52,042 | 11,056 |

| Stainless 316L | S31603 | 1/4 | 0.250 | 0.035 | 5,939 | 24,474 | 6,621 |

| Stainless 316L | S31603 | 1/4 | 0.250 | 0.049 | 8,572 | 35,322 | 8,632 |

| Stainless 316L | S31603 | 1/4 | 0.250 | 0.065 | 11,694 | 48,166 | 10,562 |

| Stainless 316L | S31603 | 3/8 | 0.375 | 0.035 | 3,818 | 15,731 | 4,659 |

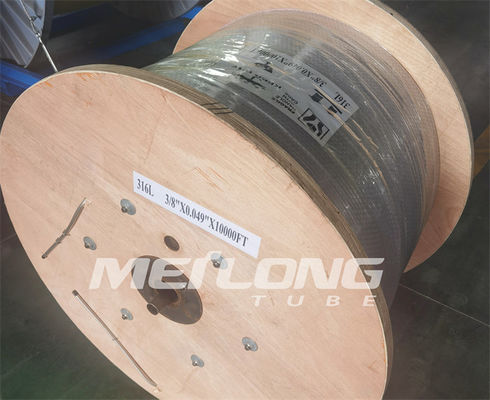

| Stainless 316L | S31603 | 3/8 | 0.375 | 0.049 | 5,483 | 22,575 | 6,222 |

| Stainless 316L | S31603 | 3/8 | 0.375 | 0.065 | 7,517 | 30,951 | 7,865 |

| Stainless 316L | S31603 | 3/8 | 0.375 | 0.083 | 9,808 | 40,372 | 9,551 |

| Stainless 316L | S31603 | 1/2 | 0.500 | 0.049 | 4,003 | 16,480 | 4,835 |

| Stainless 316L | S31603 | 1/2 | 0.500 | 0.065 | 5,461 | 22,512 | 6,206 |

| Stainless 316L | S31603 | 1/2 | 0.500 | 0.083 | 7,133 | 29,364 | 7,648 |

| Stainless 316L | S31603 | 5/8 | 0.625 | 0.049 | 3,144 | 12,955 | 3,957 |

| Stainless 316L | S31603 | 5/8 | 0.625 | 0.065 | 4,285 | 17,630 | 5,105 |

| Stainless 316L | S31603 | 5/8 | 0.625 | 0.083 | 5,472 | 22,513 | 6,519 |

| Stainless 316L | S31603 | 3/4 | 0.750 | 0.049 | 2,619 | 10,791 | 3,296 |

| Stainless 316L | S31603 | 3/4 | 0.750 | 0.065 | 3,570 | 14,686 | 4,283 |

| Stainless 316L | S31603 | 3/4 | 0.750 | 0.083 | 4,558 | 18,753 | 5,431 |

Applications:

The professionals from Meilong Tube can help you select appropriate corrosion resistant alloys to handle your well fluids. We can increase the longevity and safety of your well by specifying alloys that can stand up to the rigors of your application.

Our alloys can be used for specific applications such as hydraulic power, single transmission, monitoring and control equipment, chemical injection lines, downhole safety valve control, subsea safety valve control, umbilical control lines, topside instrumentation and impulse lines, wellhead control panel, and downhole gauge cable.

In addition, our long length alloy tubing in coils are used extensively for chemical injection and hydraulic control in subsea and onshore wells. Due to its continuous length without orbital welds, potential defects and failures can be greatly reduced. Moreover, the inner surface of the tubing coils are smooth and clean, the perfect material for hydraulic and chemical injection systems. Such coils offer fast hydraulic response time, superior collapse strength, and it blocks methanol permeation.

Customization:

Hydraulic Control Line

Brand Name: Meilong Tube

Model Number: 1/4''OD x 0.049''WT

Place of Origin: China

Certification: ISO9001

Minimum Order Quantity: 1 coil

Packaging Details: Wooden case

Delivery Time: In 7 days

Payment Terms: T/T, L/C

Supply Ability: 150 metric tons per month

Pressure Range: Extremely High Pressure

Test: 100% Length Is Hydraulic Tested

Condition: Annealing

Connection Type: Ferrule Fittings

Feature: High Tensile Strength

Highlight of 316L Hydraulic Control Line

Meilong Tube 316L Hydraulic Control Line offers superior corrosion resistance and extreme high pressure resistance that is perfect for industrial and commercial applications. Our stainless steel Hydraulic Control Line is precision-made with high tensile strength, and 100% length is hydraulic tested for maximum performance. It is annealing for easy connection of ferrule fittings and comes with ISO9001 certification. Connect with us now to get your 316L Hydraulic Control Line today!

Support and Services:

Hydraulic Control Line: Technical Support & Services

- Provide technical advice and support on the installation, operation and maintenance of hydraulic control lines.

- Design hydraulic control lines that meet customer requirements.

- Provide emergency repair services.

- Provide on-site training and seminars.

- Provide maintenance and repair services.

- Carry out regular inspections of hydraulic control lines.

- Provide spare parts and accessories.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!