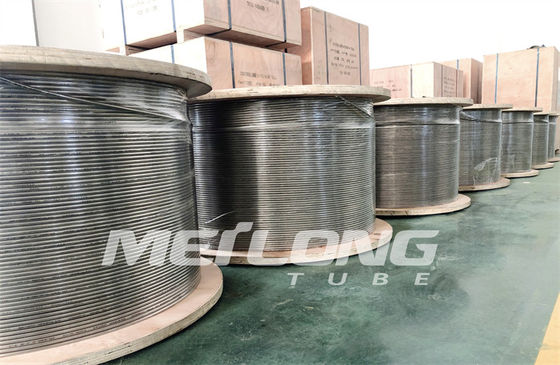

Stainless Steel 316L Capillary Coiled Tubing With High Tensile Strength And Elongation Tight Dimensional Tolerance

Product Description:

Meilong Tube's downhole control lines are designed for applications that demand durability and resistance to extreme conditions. Through tested laboratory crush results, we can provide an improved loading capability where wire-strand “bumper wires” are used.

The lines material selection is made carefully, considering factor such as bottomhole temperature, hardness, tensile and tear strength, etc, providing high hydrolytic stability. In addition, they can work under various pressure of gas.

The use of TP316L, an austenitic chromium-nickel stainless steel with low carbon content, gives excellent corrosion resistance, including organic acids, inorganic acids and salt solutions. This kind of steel is also resistant to stress corrosion cracking and pitting, with higher intergranular corrosion than other kinds.

Features:

Control lines, designed to ensure maximum reliability, can be delivered in orbital-weld-free lengths up to 40,000 ft (12,192 m).

To facilitate operation and handling during deployment, a wide range of single, dual, or triple flat-packs is available to be combined with downhole electrical cables and/or bumper wires.

Seamless or Welded-and-plug-drawn production method is adopted in the designing process, ensuring a smooth, round tube, and thereby ensuring long-term metal sealing of terminations.

In order to guarantee longevity and reliability, encapsulation materials are carefully selected to meet specific well conditions.

Technical Parameters:

<

| Alloy |

UNS |

O.D. (inch) |

W.T. (inch) |

Working Pressure (psi) |

Burst Pressure (psi) |

Collapse Pressure (psi) |

Test Pressure (psi) |

| Incoloy 825 |

N08825 |

1/8 |

0.125 |

0.028 |

12,389 |

45,914 |

11,266 |

| Incoloy 825 |

N08825 |

1/8 |

0.125 |

0.035 |

15,486 |

57,392 |

14,083 |

| Incoloy 825 |

N08825 |

1/4 |

0.250 |

0.035 |

7,281 |

26,992 |

8,427 |

| Incoloy 825 |

N08825 |

1/4 |

0.250 |

0.049 |

10,518 |

38,957 |

10,979 |

| Incoloy 825 |

N08825 |

1/4 |

0.250 |

0.065 |

14,335 |

53,127 |

13,445 |

| Incoloy 825 |

N08825 |

3/8 |

0.375 |

0.035 |

4,683 |

17,347 |

5,918 |

| Incoloy 825 |

N08825 |

3/8 |

0.375 |

0.049 |

6,720 |

24,903 |

7,919 |

| Incoloy 825 |

N08825 |

3/8 |

0.375 |

0.065 |

9,214 |

34,142 |

10,022 |

| Incoloy 825 |

N08825 |

3/8 |

0.375 |

0.083 |

12,018 |

44,526 |

12,174 |

| Incoloy 825 |

N08825 |

1/2 |

0.500 |

0.049 |

4,912 |

18,173 |

6,164 |

| Incoloy 825 |

N08825 |

1/2 |

0.500 |

0.065 |

6,701 |

24,831 |

7,905 |

| Incoloy 825 |

N08825 |

1/2 |

0.500 |

0.083 |

8,740 |

32,382 |

9,736 |

| Incoloy 825 |

N08825 |

5/8 |

0.625 |

0.049 |

3,930 |

14,538 |

4,931 |

| Incoloy 825 |

N08825 |

5/8 |

0.625 |

0.065 |

5,361 |

19,865 |

6,324 |

| Incoloy 825 |

N08825 |

5/8 |

0.625 |

0.083 |

6,846 |

25,367 |

8,076 |

| Incoloy 825 |

N08825 |

3/4 |

0.750 |

0.049 |

3,273 |

12,110 |

4,108 |

| Incoloy 825 |

N08825 |

3/4 |

0.750 |

0.065 |

4,466 |

16,547 |

5,268 |

| Incoloy 825 |

N08825 |

3/4 |

0.750 |

0.083 |

5,703 |

21,131 |

6,727 |

Applications:

When it comes to oil and gas well systems, there are many different types of lines used to complete the system. These include the Control Line, the Chemical Injection Line, the Electrical Line, the Multi-line Flat Pack, the Hydraulic Line, the Tubing Encapsulated Conductor, Intelligent Well Completions, and the Capillary Tubing.

The Control Line is used to control and monitor the functions of the well. It is made up of several wires and sensing devices that provide the well with feedback. The Chemical Injection Line is used to inject chemicals into the well in order to control its behavior as well as to aid in the extraction process. The Electrical Line supplies necessary power to the well. The Multi-line Flat Pack is a type of power and communication cable that is able to run multiple lines in a single bundle. The Hydraulic Line is used for hydraulic operations, such as closing and opening valves or providing pressure for task-specific activities. The Tubing Encapsulated Conductor is a type of conductor that is encased in a protective tubing to help protect it from the harsh environment of the oil and gas well. Intelligent Well Completions are a set of sensors, controllers, and software that are used to monitor and make decisions about the well’s operations. And finally, the Capillary Tubing is a type of flexible tubing that is used in the extraction process to transport the oil and gas from the well.

Customization:

Meilong Tube offers custom Capillary Coiled Tubing solutions for hydraulic control line and chemical injection applications. Our tubes feature Brand Name: Meilong Tube, Model Number: 1/4''OD x 0.049''WT, Place of Origin: China, Certification: ISO9001, Minimum Order Quantity: 1 coil, Packaging Details: Wooden case, Delivery Time: In 7 days, Payment Terms: T/T, L/C, Supply Ability: 150 metric tons per month, Use purpose: Hydraulic Control And Chemical Injection, Size: Tight Dimensional Tolerance, Standard: ASTM A269, Test: 100% Length Is Hydrostatic Tested, Working pressure: Above 10000 Psi. We specialize in stainless steel capillary coiled tubing and inconel 625 capillary coiled tubing.

Support and Services:

Capillary Coiled Tubing Technical Support and Service

We provide comprehensive technical support and service for all our Capillary Coiled Tubing products. Our experienced team of engineers and technicians can help you with any technical questions you may have.

We can provide advice on installation, maintenance and troubleshooting. We also offer technical seminars and training courses to ensure that you get the most out of your Capillary Coiled Tubing products.

We are committed to providing the highest quality of customer service. We can provide 24/7 technical support and advice for any problems that you may encounter.

Our team of experts can also help you with any custom design requirements that you may have. Whether you need to modify an existing design or create a completely new one, we can provide the technical assistance that you need.

If you have any questions or concerns about our Capillary Coiled Tubing products, please do not hesitate to contact us. Our team of experts is here to help.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!