The range of coiled tubing is available in sizes between 0.125 inch (3.175 millimeters) to 1 inch (25.4 millimeters) in outer diameter and up to 0.083 inch (2.108 millimeters) in wall thickness. Lengths of up to 65600 feet (20,000 meters) are available for cost-effective umbilical manufacturing and more sizes within the scope can be customized, meeting special customer requirements.

As the oil and gas industry moves into deeper and harsher waters, where extreme offshore environments demand extreme safety, Meilong Tube strives to help you select the “right” corrosion resistant material for coiled umbilical tubing to improve safety and reliability. We are dedicated to driving innovation and advancement in this field.

We are committed to bringing global customers most cost-effective tubing products, ensuring a comprehensive supply guarantee regarding the complete value-added chain in tubing production. This, along with our high-performing products and customer satisfaction, is the power of our company.

Features:

Incoloy Alloy 825

Incoloy alloy 825 is a nickel-iron-chromium alloy with additions of molybdenum and copper. This nickel steel alloy’s chemical composition is designed to provide exceptional resistance to many corrosive environments. It is similar to alloy 800 but has improved resistance to aqueous corrosion.

It has excellent resistance to both reducing and oxidizing acids, to stress-corrosion cracking, and to localized attack such as pitting and crevice corrosion. Alloy 825 is especially resistant to sulfuric and phosphoric acids. This nickel steel alloy is used for chemical processing, pollution-control equipment, oil and gas well piping, nuclear fuel reprocessing, acid production, and pickling equipment.

Characteristics

- Excellent resistance to reducing and oxidizing acids

- Good resistance to stress-corrosion cracking

- Satisfactory resistance to localized attack like pitting and crevice corrosion

- Very resistant to sulfuric and phosphoric acids

- Good mechanical properties at both room and elevated temperatures up to approximately 1020° F

- Permission for pressure-vessel use at wall temperatures up to 800°F

Technical Parameters:

Incoloy 825

Nickel:38.0%-46.0% Chromium:19.5%-23.5% Iron:22.0% Molybdenum:2.5%-3.5% Carbon:0.05% Manganese:1.0% Silicon:0.5% Sulfur:0.03% Aluminum:0.2% Titanium:0.6%-1.2% Copper:1.5%-3.0%

Norm Equivalence

Grade:Alloy ASTM/ASME:UNS No:N08825 Euro norm No:2.4858 Euro norm Name:NiCr21Mo

Dimension Tolerance

ASTM B704 / ASME SB704:UNS N08825:UNS N06625 ASTM B751 / ASME SB751:Size OD:1/8’’≤OD<5/8’’ (3.18≤OD<15.88 mm) 5/8≤OD≤1’’ (15.88≤OD≤25.4 mm) Tolerance OD:±0.004’’ (±0.10 mm) ±0.0075’’ (±0.19 mm) Tolerance WT:±12.5%

Meilong Tube Standard

Size OD:1/8’’≤OD<5/8’’ (3.18≤OD<15.88 mm) 5/8≤OD≤1’’ (15.88≤OD≤25.4 mm) Tolerance OD:±0.004’’ (±0.10 mm) Tolerance WT:±10% ±8%

Applications:

Nickel alloy tubing provides high-grade control line properties that are beneficial for a variety of operational requirements. This tubing is available as seamless and floating internal plug redrawn tubing, which is supplied in the annealed condition. Additionally, it comes in continuous lengths with no orbital joint welds.

The following table outlines the alloy, UNS, O.D., W.T., working pressure, burst pressure, collapse pressure and test pressure for each specification for Incoloy 825:

| Alloy |

UNS |

O.D. (inch) |

W.T. (inch) |

Working Pressure (psi) |

Burst Pressure (psi) |

Collapse Pressure (psi) |

Test Pressure (psi) |

| Incoloy 825 |

N08825 |

1/8 |

0.125 |

0.028 |

12,389 |

45,914 |

11,266 |

| Incoloy 825 |

N08825 |

1/8 |

0.125 |

0.035 |

15,486 |

57,392 |

14,083 |

| Incoloy 825 |

N08825 |

1/4 |

0.250 |

0.035 |

7,281 |

26,992 |

8,427 |

| Incoloy 825 |

N08825 |

1/4 |

0.250 |

0.049 |

10,518 |

38,957 |

10,979 |

| Incoloy 825 |

N08825 |

1/4 |

0.250 |

0.065 |

14,335 |

53,127 |

13,445 |

| Incoloy 825 |

N08825 |

3/8 |

0.375 |

0.035 |

4,683 |

17,347 |

5,918 |

| Incoloy 825 |

N08825 |

3/8 |

0.375 |

0.049 |

6,720 |

24,903 |

7,919 |

| Incoloy 825 |

N08825 |

3/8 |

0.375 |

0.065 |

9,214 |

34,142 |

10,022 |

| Incllooy 825 |

N08825 |

3/8 |

0.375 |

0.083 |

12,018 |

44,526 |

12,174 |

| Incoloy 825 |

N08825 |

1/2 |

0.500 |

0.049 |

4,912 |

18,173 |

6,164 |

| Incoloy 825 |

N08825 |

1/2 |

0.500 |

0.065 |

6,701 |

24,831 |

7,905 |

| Incoloy 825 |

N08825 |

1/2 |

0.500 |

0.083 |

8,740 |

32,382 |

9,736 |

| Incoloy 825 |

N08825 |

5/8 |

0.625 |

0.049 |

3,930 |

14,538 |

4,931 |

| Incoloy 825 |

N08825 |

5/8 |

0.625 |

0.065 |

5,361 |

19,865 |

6,324 |

| Incoloy 825 |

N08825 |

5/8 |

0.625 |

0.083 |

6,846 |

25,367 |

8,076 |

| Incoloy 825 |

N08825 |

3/4 |

0.750 |

0.049 |

3,273 |

12,110 |

4,108 |

| Incoloy 825 |

N08825 |

3/4 |

0.750 |

0.065 |

4,466 |

16,547 |

5,268 |

| Incoloy 825 |

N08825 |

3/4 |

0.750 |

0.083 |

5,703 |

21,131 |

6,727 |

Moreover, the theoretical burst and collapse pressures are based on minimum wall thickness and minimum tensile strength/minimum yield strength respectively. All the pressure ratings are valid for 100°F (38°C) neutral and static conditions.

Customization:

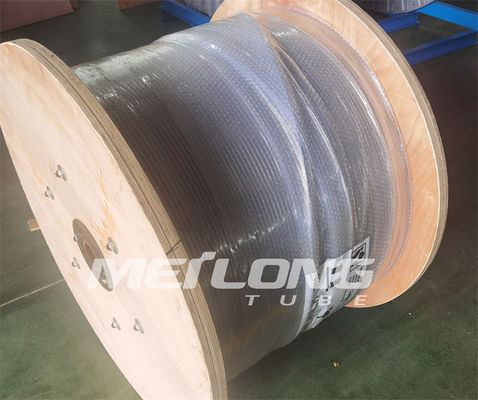

Meilong Tube provides custom service of Nickel Alloy Tubing Control Line, Nickel Alloy Tubing Capillary Tube, and Nickel Alloy Tubing Capillary Tubing with its Brand Name. The Model Number is 1/4'' OD x 0.049'' WT. The product is ISO9001 certified and manufactured in China. The minimum order quantity is 1 coil. It is packaged in Wooden case. The delivery time is In 7 days. The payment terms are T/T, L/C. The supply ability is 150 metric tons per month. The NDT is 100% Length Is Eddy Current Tested. The pressure rate is above 10000 Psi. It is cold drawing process. It has continuous length without orbital welds. The surface is highly clean and bright.

Support and Services:

Nickel Alloy Tubing Technical Support and Service:

We provide technical support and services for our Nickel Alloy Tubing products, including but not limited to:

- Product design & development

- Process optimization & improvement

- Failure analysis & troubleshooting

- Material selection & specification

- Process validation & certification

- Test & inspection

- Shipping & logistics

For more information about our Nickel Alloy Tubing Technical Support and Service, please contact us.

Packing and Shipping:

Nickel Alloy Tubing Packaging and Shipping

We use specially designed packaging materials and techniques to ensure that our Nickel Alloy Tubing is in perfect condition when it arrives at its destination. Our packaging includes heavy-duty cardboard boxes with foam inserts to keep the tubing safe. We also use bubble wrap and other protective materials to prevent any movement within the package. We ship our products using reliable and secure delivery services that provide tracking and insurance for all orders. We also offer expedited shipping for customers who need their orders quickly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!