Inconel 625 Capillary Nickel Alloy Tubing Up to 12000 Meters with Close Dimensional Tolerance

Product Description:

Meilong Tube manufactures high quality coiled tubing which is made from corrosion-resistant austenitic, duplex, super duplex stainless steel and nickel alloy grades. These products are often used in hydraulic power control lines, chemical injection lines, and umbilicals and instrumentation tubing in the upstream oil and gas industry.

In terms of size coils range from 0.125 inch (3.175 millimeters) to 1 inch (25.4 millimeters) in terms of outer diameter with wall thicknesses up to 0.083 inch (2.108 millimeters). Lengths of 65600 feet (20,000 meters) can be achieved offering cost-effective umbilical manufacturing. Furthermore, more sizes can be customized to meet special requirements.

Our main goal is to help customers use the “right” corrosion resistant material in coiled umbilical tubing to improve the safety and reliability of their work. This is why we strive for innovative and continuous development in this area.

Meilong Tube works hard to bring global customers the most cost-effective tubing products by ensuring a comprehensive supply guarantee in tubing production. In doing so, we strive to provide high performance products and complete customer satisfaction.

Features:

Incoloy alloy 825 is a nickel-iron-chromium alloy with additions of molybdenum and copper. This nickel steel alloy’s chemical composition is designed to provide exceptional resistance to many corrosive environments. It is similar to alloy 800 but has improved resistance to aqueous corrosion. It has excellent resistance to both reducing and oxidizing acids, to stress-corrosion cracking, and to localized attack such as pitting and crevice corrosion. Alloy 825 is especially resistant to sulfuric and phosphoric acids. This nickel steel alloy is used for chemical processing, pollution-control equipment, oil and gas well piping, nuclear fuel reprocessing, acid production, and pickling equipment.

Moreover, Incoloy 825 exhibits the following characteristics:

- Excellent resistance to reducing and oxidizing acids

- Good resistance to stress-corrosion cracking

- Satisfactory resistance to localized attack like pitting and crevice corrosion

- Very resistant to sulfuric and phosphoric acids

- Good mechanical properties at both room and elevated temperatures up to approximately 1020° F

- Permission for pressure-vessel use at wall temperatures up to 800°F

Technical Parameters:

Incoloy 825

Composition

Nickel Chromium Iron Molybdenum Carbon Manganese Silicon Sulfur Aluminum Titanium Copper % % % % % % % % % % % min. max. max. max. max. max. 38.0-46.0 19.5-23.5 22.0 2.5-3.5 0.05 1.0 0.5 0.03 0.2 0.6-1.2 1.5-3.0

Norm Equivalence

Grade UNS No Euro norm No Name Alloy ASTM/ASME EN10216-5 EN10216-5 825 N08825 2.4858 NiCr21Mo

Dimension Tolerance

ASTM B704 / ASME SB704, UNS N08825, UNS N06625 ASTM B751 / ASME SB751 Size OD Tolerance OD Tolerance WT 1/8’’≤OD<5/8’’ (3.18≤OD<15.88 mm) 5/8≤OD≤1’’ (15.88≤OD≤25.4 mm) ±0.004’’ (±0.10 mm) ±0.0075’’ (±0.19 mm) ±12.5% ±12.5%

Meilong Tube Standard

Size OD Tolerance OD Tolerance WT 1/8’’≤OD<5/8’’ (3.18≤OD<15.88 mm) 5/8≤OD≤1’’ (15.88≤OD≤25.4 mm) ±0.004’’ (±0.10 mm) ±0.004’’ (±0.10 mm) ±10% ±8%

Dimension Tolerance

ASTM B423 / ASME SB423, UNS N08825 Size OD Tolerance OD Tolerance WT 1/8’’≤OD<3/16’’ (3.18≤OD<4.76 mm) 3/16≤OD<1/2’’ (4.76≤OD<12.7 mm) 1/2’’≤OD≤1’’ (12.7≤OD≤25.4 mm) +0.003’’ (+0.08 mm) / -0 +0.004’’ (+0.10 mm) / -0 +0.005’’ (+0.13 mm) / -0 ±10% ±10% ±10%

Meilong Tube Standard

Size OD Tolerance OD Tolerance WT 1/8’’ ≤OD<3/16’’ (3.18≤OD<4.76 mm) 3/16≤OD<1/2’’ (4.76≤OD<12.7 mm) 1/2’’≤OD≤1’’ (12.7≤OD≤25.4 mm) +0.003’’ (+0.08 mm) / -0 +0.004’’ (+0.10 mm) / -0 +0.004’’ (+0.10 mm) / -0 ±10% ±10% ±8%

Applications:

Nickel alloy tubing is a kind of control line with properties of seamless & floating internal plug redrawn tubing, supplied in the annealed condition. It is continuous length without orbital joint welds, and it has following characteristics:

- Theoretical burst pressure is based on minimum wall thickness, and minimum tensile strength.

- Theoretical collapse pressure is based on minimum wall thickness, and minimum yield strength.

- Pressure rating is at 100°F (38°C), neutral and static conditions.

The parameters related to nickel alloy tubing are listed below:

| Alloy |

UNS |

O.D. |

W.T. |

Working Pressure |

Burst Pressure |

Collapse Pressure |

Test Pressure |

| Incoloy 825 |

N08825 |

1/8 |

0.125 |

0.028 |

12,389 |

45,914 |

11,266 |

| Incoloy 825 |

N08825 |

1/8 |

0.125 |

0.035 |

15,486 |

57,392 |

14,083 |

| Incoloy 825 |

N08825 |

1/4 |

0.250 |

0.035 |

7,281 |

26,992 |

8,427 |

| Incoloy 825 |

N08825 |

1/4 |

0.250 |

0.049 |

10,518 |

38,957 |

10,979 |

| Incoloy 825 |

N08825 |

1/4 |

0.250 |

0.065 |

14,335 |

53,127 |

13,445 |

| Incoloy 825 |

N08825 |

3/8 |

0.375 |

0.035 |

4,683 |

17,347 |

5,918 |

| Incoloy 825 |

N08825 |

3/8 |

0.375 |

0.049 |

6,720 |

24,903 |

7,919 |

| Incoloy 825 |

N08825 |

3/8 |

0.375 |

0.065 |

9,214 |

34,142 |

10,022 |

| Incoloy 825 |

N08825 |

3/8 |

0.375 |

0.083 |

12,018 |

44,526 |

12,174 |

| Incoloy 825 |

N08825 |

1/2 |

0.500 |

0.049 |

4,912 |

18,173 |

6,164 |

| Incoloy 825 |

N08825 |

1/2 |

0.500 |

0.065 |

6,701 |

24,831 |

7,905 |

| Incoloy 825 |

N08825 |

1/2 |

0.500 |

0.083 |

8,740 |

32,382 |

9,736 |

| Incoloy 825 |

N08825 |

5/8 |

0.625 |

0.049 |

3,930 |

14,538 |

4,931 |

| Incoloy 825 |

N08825 |

5/8 |

0.625 |

0.065 |

5,361 |

19,865 |

6,324 |

| Incoloy 825 |

N08825 |

5/8 |

0.625 |

0.083 |

6,846 |

25,367 |

8,076 |

| Incoloy 825 |

N08825 |

3/4 |

0.750 |

0.049 |

3,273 |

12,110 |

4,108 |

| Incoloy 825 |

N08825 |

3/4 |

0.750 |

0.065 |

4,466 |

16,547 |

5,268 |

| Incoloy 825 |

N08825 |

3/4 |

0.750 |

0.083 |

5,703 |

21,131 |

6,727 |

Nickel alloy tubing is a kind of control line that has various parameters related. These parameters can be referred from the table above.

Customization:

Customized Capillary Nickel Alloy Tubing

Meilong Tube offers customized Capillary Nickel Alloy Tubing to meet specific requirements. The model number is 1/4''OD x 0.049''WT. Meilong Tube is one of the leading manufacturers in China who is certified with ISO9001. The minimum order quantity is 1 coil and the packaging details are wooden case. Meilong Tube guarantees delivery time in 7 days and our payment terms are T/T, L/C. We can supply up to 150 metric tons per month. The length of the Nickel Alloy Tubing is up to 12000 Meters and it is annealed with close dimensional tolerance. The process is cold drawing and 100% length is eddy current tested. Our Nickel Alloy Tubing is used for capillary tubing, hydraulic control line and other applications.

Support and Services:

Nickel Alloy Tubing Technical Support and Service

We offer technical support and service for Nickel Alloy Tubing. Our knowledgeable staff can provide assistance with product selection, installation, troubleshooting and general maintenance.

We offer a variety of resources to assist you in utilizing our Nickel Alloy Tubing, such as detailed product specifications, installation instructions, and product maintenance tips.

Additionally, our experienced team is available to answer any questions you may have regarding our products. We strive to provide fast and reliable service, ensuring your satisfaction.

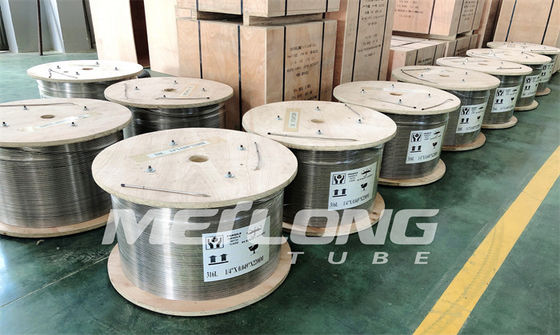

Packing and Shipping:

Nickel Alloy Tubing Packaging and Shipping

Nickel Alloy Tubing is typically packaged and shipped in bundles, depending on the size and length of the product. The bundles are wrapped in plastic and secured with nylon straps to protect the tubing from moisture, dust, and damage during transit. Once the bundles are securely fastened, the tubing is loaded onto a pallet and wrapped in plastic sheeting for additional protection. The pallet is then loaded onto a truck for delivery.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!