Product Description:

Meilong Tube TEC - Quality Unique Products

Meilong Tube's TEC products offer a range of unique capabilities. Flatpacks can be custom-made with copper components, hydraulic control and chemical injection lines. Each individual piece and tube can be colored-coded and have custom printing to make installation easier. The company operates an entirely vertically integrated production facility which ensures swift delivery, thorough quality control and the widest range of available configurations.

The choice of tubing is based on well conditions including factors such as pressure, temperature and corrosiveness. It is produced using materials best suited to the application, followed by longitudinal welding, eddy current testing and then drawn to finished size. Comprehensive test data is provided for every tube. By opting for TEC, customers can benefit from the almost limitless selection of components in custom lengths without the need for splicing. In addition, Meilong Tube now provides standard encapsulation sizes of 11 mm x 11 mm square to meet the most exacting requirements. Lastly, composite cables incorporating various combinations of electrical and optical components can be supplied to match any special downhole requirements.

Features:

There are a number of materials used to assure that components are encapsulated, insulated and protected. The abbreviation, generic and trade names of some of these materials, as well as the minimum installation temperature of their encapsulation materials, are described below:

ECTFE - Ethylene Chlorotrifluoroethylene (Halar®): -60°C

ETFE - Ethylene Tetrafluoroethylene (Tefzel®): -60°C

FEP - Fluorinated Ethylene Propylene (Teflon® FEP): -100°C

HDPE - High Density Polyethylene: -40°C

PFA - Perfluoroalkoxy (Teflon® PFA): -100°C

PA - Polyamide (Nylon): -40°C

PP - Polypropylene: -10°C

PVDF - Polyvinylidene Fluoride (Kynar®): -20°C

TPO-PP -Thermoplastic polyolefin (Santoprene®): -20°C

Technical Parameters:

Mechanical Characteristics for Alloy TEC, Cold Worked

The table below shows the mechanical characteristics for alloy TEC when cold worked:

| Diameter | Wall Thickness | Stainless 316L (psi) | Incoloy 825 (psi) | Minimum Bend Radius* (inches) |

|---|

| 0.125 (1/8) | 0.022 | 23,882 | 25,209 | 0.75 |

| 0.250 (1/4) | 0.028 | 16,371 | 17,281 | 1.50 |

| 0.250 (1/4) | 0.035 | 19,688 | 20,781 | 1.50 |

| 0.250 (1/4) | 0.049 | 26,173 | 27,627 | 1.50 |

| 0.375 (3/8) | 0.035 | 13,783 | 14,549 | 2.25 |

| 0.375 (3/8) | 0.049 | 18,739 | 19,780 | 2.25 |

These calculations are based on the minimum yield strength of 120,000 psi. All TEC tubing is oversized welded and drawn and can be custom printed with a variety of data including part number, serial number, sequential length and purchase order number.

The indicated bending radius is in static condition after final training at the termination. All bending must be performed using a tubing bender to ensure that the bending radius is uniform. When deploying the tubing into or out of the well, the minimum bending radius should be as large as possible.

Electrical Components

The table below shows the electrical components of the TEC styles:

| TEC Style | TEC 100 | TEC 150 | TEC 175 | TEC 200 | TEC 250 |

|---|

| Temperature Range | -10 to 100°C | -10 to 150°C | -100 to 175°C | -100 to 200°C | -100 to 250°C |

| Filler | PP | PP | FEP | FEP | PFA |

| Insulation | PP | FEP | FEP | FEP | PFA |

The table below shows the maximum electrical conductor resistance at 20°C (68°F) for both solid bare copper and 7 strands bare copper:

| Conductor O.D. AWG | inches | mm | Solid Bare Copper (Ohms/kft) | Solid Bare Copper (Ohms/m) | 7 Strands Bare Copper (Ohms/kft) | 7 Strands Bare Copper (Ohms/m) |

|---|

| 18 | 0.0403 | 1.02 | 6.52 | 21.4 | 6.66 | 21.8 |

| 17 | 0.0453 | 1.15 | 5.15 | 16.9 | 5.27 | 17.3 |

| 16 | 0.0508 | 1.29 | 4.10 | 13.5 | 4.18 | 13.7 |

| 15 | 0.0571 | 1.45 | 3.24 | 10.6 | 3.31 | 10.9 |

| 14 | 0.0641 | 1.63 | 2.57 | 8.45 | 2.62 | 8.62 |

| 13 | 0.0720 | 1.83 | 2.04 | 6.69 | 2.08 | 6.82 |

| 12 | 0.0808 | 2.05 | 1.62 | 5.31 | 1.65 | 5.43 |

| 11 | 0.0907 | 2.30 | 1.29 | 4.22 | 1.32 | 4.30 |

| 10 | 0.102 | 2.59 | 1.019 | 3.34 | 1.039 | 3.41 |

| 9 | 0.114 | 2.90 | 0.808 | 2.65 | 0.825 | 2.71 |

| 8 | 0.128 | 3.25 | 0.641 | 2.10 | 0.654 | 2.14 |

| 7 | 0.144 | 3.66 | 0.512 | 1.68 | 0.522 | 1.72 |

| 6 | 0.162 | 4.12 | 0.409 | 1.34 | 0.416 | 1.37 |

Applications:

The oil and gas industry presents several specific challenges when it comes to pressure and temperature monitoring down hole. Taking measurements in such a grueling and hostile environment can be difficult, as various conditions, such as high temperatures, pressure, corrosive gases and liquid streams, can interfere with the performance of any instrument deployed.

These conditions can affect the accuracy of the results from any temperature or pressure sensing instrument. Numerous robust technologies have been developed to enable the successful operation of sensing applications in the oil and gas industry, where extreme conditions and hostile environments are commonplace.

Customization:

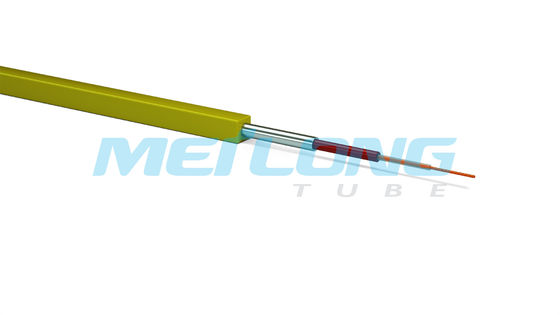

Meilong Tube 316L Tubing Encapsulated Cable

Brand Name: Meilong Tube

Model Number: 1/4''OD x 0.049''WT

Place of Origin: China

Certification: ISO9001

Minimum Order Quantity: 2 coils

Packaging Details: Wooden case

Delivery Time: In 7 days

Payment Terms: T/T, L/C

Supply Ability: 150 metric tons per month

Insulation Material: PP, FEP, PFA

Insulation Temperature: -10°C To 250°C

Jacket Material: PVDF, FEP, Nylon 11

Conductor: Copper Wires, Tinplated Copper Wires, Stranded Wires, Optical Fibers

Tubing Condition: Cold Worked

Features: Meilong Tube 316L Tubing Encapsulated Cable features high-quality Tubing Encapsulated Conductor and Tubing Encapsulated Conductor Cable, which has excellent electrical properties, corrosion resistance, and temperature resistance. This Tubing Encapsulated Cable is perfect for various applications.

Support and Services:

Technical Support and Service for Tubing Encapsulated Cable:

- 24/7 technical support through our customer service representatives

- Online troubleshooting and technical advice

- Installation and maintenance instructions

- Comprehensive warranty coverage

- Quick response to inquiries

- Free replacement of defective products

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!