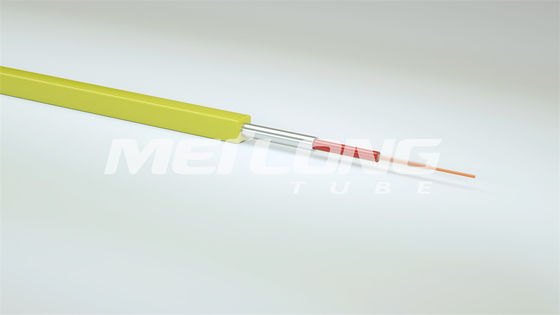

PVDF Jacket Tubing Encapsulated Conductor with 316L Tubing Material -10°C to 250°C Insulation Temperature

Product Description:

Flatpacks supplied by Meilong Tube TEC production can not only include copper components, hydraulic control and chemical injection lines but also contain individual components and tubes which can be color-coded and finished with custom printing in order to facilitate ease of assembly. In addition, its vertical integrated production guarantees immediate delivery, while maximising quality control and providing a wide variety of configurations.

The tubing used is selected based on multiple factors such as pressure, temperature and the corrosive nature of the fluid, where the alloy of the tubing must match the application precisely. After getting welded longitudinal and undergoing eddy current testing, the tubes are then produced to its specified size, each data of which are well documented.

The custom length flatpacks come with an almost infinite combination of the components included, all of which are splice-free. To meet almost any downhole requirements, standard encapsulation sizes (11 mm x 11 mm square) are also available. Furthermore, composite cables with different combinations of electric and optical elements serves as the primary means of providing a customised solution to any specific downhole needs.

Features:

Encapsulation, Insulation and Filler Materials are essential parts of any electric and electronic devices, which provide safety by preventing physical contact and by guarding against external environments. Here is a table of the information about the most commonly used materials:

| Abbreviation |

Generic Name |

Trade Name |

Minimum Installation Temperature of Encapsulation Materials |

| ECTFE |

Ethylene Chlorotrifluoroethylene |

Halar® |

-60°C |

| ETFE |

Ethylene Tetrafluoroethylene |

Tefzel® |

-60°C |

| FEP |

Fluorinated Ethylene Propylene |

Teflon® FEP |

-100°C |

| HDPE |

High Density Polyethylene |

|

-40°C |

| PFA |

Perfluoroalkoxy |

Teflon® PFA |

-100°C |

| PA |

Polyamide |

Nylon |

-40°C |

| PP |

Polypropylene |

|

-10°C |

| PVDF |

Polyvinylidene Fluoride |

Kynar® |

-20°C |

| TPO-PP |

Thermoplastic polyolefin |

Santoprene® |

-20°C |

In summary, these materials have different performances in terms of their thermal resistance and physical properties. Depending on the specific application, proper selection of materials is crucial for the overall performance of the device.

Technical Parameters:

Mechanical Characteristics for Alloy TEC, Cold Worked

The tables below show the diameter, wall thickness, stainless 316L minimum collapse and Incoloy 825 minimum collapse and minimum bend radius (in inches) of Alloy TEC cold worked.

| Diameter (inches) |

Wall Thickness (inches) |

Stainless 316L (psi) |

Incoloy 825 (psi) |

Minimum Bend Radius (inches) |

| 0.125 (1/8) |

0.022 |

23,882 |

25,209 |

0.75 |

| 0.250 (1/4) |

0.028 |

16,371 |

17,281 |

1.50 |

| 0.250 (1/4) |

0.035 |

19,688 |

20,781 |

1.50 |

| 0.250 (1/4) |

0.049 |

26,173 |

27,627 |

1.50 |

| 0.375 (3/8) |

0.035 |

13,783 |

14,549 |

2.25 |

| 0.375 (3/8) |

0.049 |

18,739 |

19,780 |

2.25 |

The calculations are based on the minimum yield strength of 120,000 psi. All TEC tubing is oversized welded and drawn, which can be custom printed with a variety of data including part number, serial number, sequential length and purchase order number. When doing the bending, the bending radius should be as large as possible. At the same time, a tubing bender should be used to ensure that the bending radius is uniform.

Electrical Components

| TEC Style |

TEC 100 |

TEC 150 |

TEC 175 |

TEC 200 |

TEC 250 |

| Temperature Range |

-10 to 100°C |

-10 to 150°C |

-100 to 175°C |

-100 to 200°C |

-100 to 250°C |

| Filler |

PP |

PP |

FEP |

FEP |

PFA |

| Insulation |

PP |

FEP |

FEP |

FEP |

PFA |

The maximum electrical conductor resistance data at 20°C (68°F) of the given AWG cables are listed in the table below.

| Conductor O.D. (AWG) |

Conductor O.D. (inches) |

Solid Bare Copper (Ohms / kft) |

7 Strands Bare Copper (Ohms / m) |

Ohms / kft |

Ohms / m |

| 18 |

0.0403 |

1.02 |

6.52 |

21.4 |

6.66 |

| 17 |

0.0453 |

1.15 |

5.15 |

16.9 |

5.27 |

| 16 |

0.0508 |

1.29 |

4.10 |

13.5 |

4.18 |

| 15 |

0.0571 |

1.45 |

3.24 |

10.6 |

3.31 |

| 14 |

0.0641 |

1.63 |

2.57 |

8.45 |

2.62 |

| 13 |

0.0720 |

1.83 |

2.04 |

6.69 |

2.08 |

| 12 |

0.0808 |

2.05 |

1.62 |

5.31 |

1.65 |

| 11 |

0.0907 |

2.30 |

1.29 |

4.22 |

1.32 |

| 10 |

0.102 |

2.59 |

1.019 |

3.34 |

1.039 |

| 9 |

0.114 |

2.90 |

0.808 |

2.65 |

0.825 |

| 8 |

0.128 |

3.25 |

0.641 |

2.10 |

0.654 |

Applications:

In oil and gas industry, measuring pressure and temperature in the down hole is holds a growing cruciality. With advanced sensors, the wells can be monitored in depth to ensure the desired results.

From measuring temperature, it helps to better understand the interaction between subsurface and surface. Moreover, detecting the pressure in the down hole provides the information to prevent the risk of drilling into unexpected subsurface structures.

So, as more oil wells are drilled and as more exploration continues, the importance of taking accurate temperature and pressure measurements during drilling process continues to increase.

Customization:

Welcome to Meilong Tube for customizing your own Stainless Steel Tubing Encapsulated Cable. Our Tubing Encapsulated Cable is made of 316L Tubing Encapsulated Conductor, which is great for insulation temperature from -10°C to 250°C. And the tubing material is made of 316L and Incoloy 825, with tubing size of 1/4''x0.035'', 3/8''x0.049''. The tubing condition is cold worked, and the insulation material can be PP, FEP, and PFA. All our products are certified by ISO9001.

Minimum order quantity for our Tubing Encapsulated Cable is 2 coils. And we can promise a fast delivery within 7 days. We accept payment terms such as T/T and L/C. Our monthly supply ability is 150 metric tons. The packaging is wooden case.

Support and Services:

Technical support and service for Tubing Encapsulated Cable:

- Provide technical consultation and troubleshooting services.

- Provide maintenance services and components for Tubing Encapsulated Cable.

- Provide installation services for Tubing Encapsulated Cable.

- Provide remote diagnostic services for Tubing Encapsulated Cable.

- Provide product upgrade services for Tubing Encapsulated Cable.

- Provide software updates for Tubing Encapsulated Cable.

- Provide customer repair and warranty services for Tubing Encapsulated Cable.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!